Machining of plastics, non-ferrous metals and steel is a wide range of services that allow us to create parts and details of any level of complexity, while ensuring high precision in their manufacture. We provide machining services using dedicated machines and equipment. We have modern machinery for machining engineering plastics, aluminum, brass and steel.

Our offer includes services such as:

- CNC machining of aluminum,

- CNC machining of steel,

- CNC machining of plastics,

Basic services include primarily CNC milling and CNC turning, however our machine park allows us to perform other machining work as well, including cutting and CNC cutting.

High-quality services: Machining of plastics, non-ferrous metals and steel

With the latest digital CNC machine tools and qualified personnel, we are able to manufacture complex parts with high accuracy and repeatability. We execute large series and single orders, which are made on the basis of technical drawings or based on patterns. This allows us to carry out orders for standard elements, as well as non-standard orders. In this regard, we cooperate with companies representing various industries and sectors.

We work only with the highest quality materials, imported from the world's best manufacturers, and provide assistance in their proper selection for a given order. Experience, the comprehensive nature of the services provided and the machining capabilities of our CNC platforms affect the competitiveness of our offer.

What is CNC machining?

CNC machining is an advanced technological process that allows precise shaping of various materials - from plastics to aluminum and steel. Through the use of computer numerical control, processes such as milling and turning are carried out with extreme accuracy and repeatability, which is crucial in the production of complex components. Thanks to its integration with CAD/CAM software, CNC machining provides not only high precision, but also flexibility in implementing a variety of projects, making it an indispensable tool in modern industrial manufacturing.

What does CNC machining consist of?

The main idea of CNC machining is to automate production processes through computer control of machines, which ensures high accuracy, repeatability and efficiency in the production of components and parts. Integration with advanced CAD/CAM systems and continuous technological development ensure that CNC machining remains an indispensable tool in a variety of industrial sectors, contributing to innovation and improved manufacturing efficiency.

Stages and methods of CNC machining

The CNC machining process begins with the creation of a detailed 3D model of the part or product using CAD software. At this stage, the designer defines all the dimensions, shapes and technical specifications that will later be realized by the CNC machine. The CAD model is imported into the CAM software, which converts it into instructions that control the CNC machine. The CAM software generates precise toolpaths, specifying the movements, speeds, feeds and depths of cut necessary to complete the job. The instructions generated by the CAM software are converted into G-code, which is the programming language for CNC machines. The CNC machine is prepared for machining by attaching the appropriate cutting tool and base material. It is important to set up the machine and tools accurately to ensure that the operation is performed precisely according to the programmed parameters.

We can distinguish the following CNC machining methods:

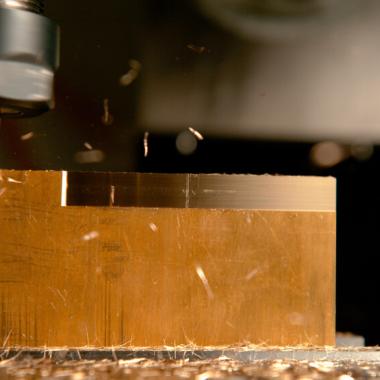

- CNC milling,

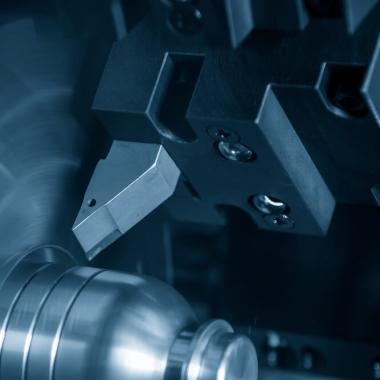

- CNC turning,

- CNC cutting,

CNC milling involves removing material with rotating cutters. The machining method is ideal for creating intricate shapes, details and surfaces with different gradients. CNC turning uses a cutting tool and the movement of the rotating material, which enables precise turning of cylindrical parts such as shafts, bushings and bolts. CNC cutting makes it possible to cut complex shapes accurately yet quickly.

Benefits of CNC machining of plastics

Plastics are materials commonly used in many industries. Thanks to the methods of working on them, we can take full advantage of the opportunities they offer. The main advantages of CNC machining are:

- high production accuracy - computer-controlled machine tools give the material the dimensions and shape that exactly match the requirements of the project,

- repeatability - based on a single design, the machine tool is capable of making virtually any number of identical parts. This allows to limit

- number of defective pieces;

- speed of work - the time required for machining a single component depends on its size and complexity, but in the case of CNC machining it is always shorter than in the case of conventional machining. The speed of work does not negatively affect the accuracy of the machine tool,

- production safety - the operation of the machine tool is largely automated, the lack of direct participation of the machine operator in machining reduces the risk of accidents at work.

All this translates significantly into lower production costs, while increasing productivity. CNC machining is primarily used in the production of mass-scale components.

CNC plastic machining: We fulfill standard and non-standard orders

Are you interested in CNC milling and turning? Do you have an unusual project and are looking for a reliable contractor? Feel free to take a detailed look at our offer, and if you have any questions or concerns, feel free to contact us.

As a CNC company, we have been successfully completing projects of varying complexity for years. We work with a wide range of plastics, while also performing entrusted machining tasks in CNC machining of aluminum and steel. This gives us a very wide range of possibilities to respond to the needs and expectations of your business.

Machining materials used by our company